Equipments

Design, Die manufacturing and Mass production

Solution to your project

We solve design, die manufacturing and mass production.

For example, die manufacturing for automobile side panels, press working up to 6 mm thick, 50t to 450t plastic molding.

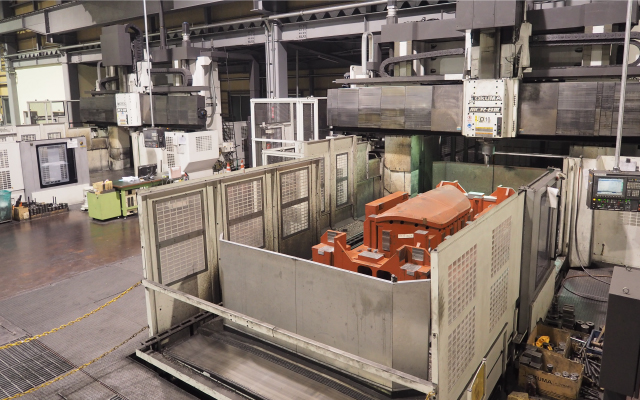

Equipment list of die manufacturing

We can solve the process from die design to first try press with a short delivery of one month.

5-Face Machining Centers

- 4000×3200×800

- 2 (OKUMA MCR-BⅡ)

- 3200×2700×650

- 2 (OKUMA MCR-AⅡ)

- 3200×1500×650

- 1 (OKUMA MCR-5A)

- 3000×5000×800

- 2 (OKUMA MCR-BⅢ)

Double-Column Machining Centers

- 4260×3150×1650

- 1 (SNK HF-5MC)

- 5250×2700×600

- 1 (SNK RB-4NMC)

- 2000×1600×400

- 1 (OKUMA MCV-A)

- 3000×1600×400

- 1 (OKUMA MCV-A)

- 3200×2700×650

- 1 (OKUMA MCV-AⅡ)

- 2000×1600×450

- 1 (OKUMA MCV-AⅡ)

- 2850×1700×400

- 1 (SNK RB-2N4MC)

- 2850×1700×400

- 1 (SNK RB-2NM)

- 1250×630×400

- 1 (OKUMA MC-60VA)

- 2050×1060×800

- 1 (OKUMA MILLAC-1052V)

- 1300×650×600

- 1 (TOSHIBA VMC650)

- 700×400×400

- 1 (HITACHI VA-40)

High-speed Machining Center

- 3300×1980×1000

- 1 (SNK DC-3FM)

Super High Speed Milling

- 600×400×250

- 1 (TOSHIBA F-MACH643)

- 600×400×450

- 1 (TOSHIBA ASV40)

Horizontal Boring Machine

- 1800×1500×1450

- 1 (TOSHIBA BT-10B)

Vertical Machining Centers

- 7 (MX-55VB etc...)

CNC Lathes

- 1 (OKUMA HL-35)

NC Surface Grinding Machine

- 600×1500

- 1 (NAGASE)

Surface Grinding Machine

- 500×1200

- 2 (OKAMOTO)

- 900×440

- 1 (HITACHI)

EDM

- 650×450×350

- 1 (MITSUBISHI M65E)

Wire EDM

- 1 (Seibu M75B)

- 1 (Seibu M50B)

- 1 (MITSUBISHI FX20)

Radial Drilling Machine

- 1600

- 4 (OOYA)

Tryout Hydraulic Presses

- 800t (2200×3000×1000)

- 1 (FUKUI)

- 500t (1400×2500×800)

- 1 (FUKUI)

- 400t (1500×2500×200)

- 1 (FUKUI)

- 200t (1700×3000×800)

- 1 (FUKUI)

Tryout Mechanical Presses

- 600t (2600×1600×1200)

- 1 (SsangYong)

- 2000t (4700×2600×1600)

- 1 (SIMPAC)

Die Spotting Press

- 50t

- 1 (AMINO)

- 30t

- 1 (KONGO)

Shearing Machine

- 1 (KOMATSU SHS6)

Equipment list of metal stamping / Injection molding

We can solve all your manufacturing requirements.

Crank presses

400t 1 (FUKUI)

160t 1 (AIDA)

150t 3 (AIDA)

150t 1 (KOMATSU)

150t 1 (NAGAO)

150t 1 (SHINOHARA)

110t 1 (KOMATSU)

40t~80t 10 (AIDA, KOMATSU, etc...)

160t 1 (AIDA)

150t 3 (AIDA)

150t 1 (KOMATSU)

150t 1 (NAGAO)

150t 1 (SHINOHARA)

110t 1 (KOMATSU)

40t~80t 10 (AIDA, KOMATSU, etc...)

Crank presses

(Progressive)

(Progressive)

500t 1 (AIDA)

300t 1 (AIDA)

300t 1 (KOMATSU)

200t 1 (AIDA)

160t 1 (AIDA)

150t 1 (AIDA)

110t 3 (AIDA)

300t 1 (AIDA)

300t 1 (KOMATSU)

200t 1 (AIDA)

160t 1 (AIDA)

150t 1 (AIDA)

110t 3 (AIDA)

Crank presses

(Auto-Hand)

(Auto-Hand)

250t 1 (KOMATSU)

200t 2 (AIDA)

75t 1 (KOMATSU)

200t 2 (AIDA)

75t 1 (KOMATSU)

Crank presses

(Linepacer)

(Linepacer)

200t×2、150t×4 6 (AIDA)

200t×6、150t×1 7 (AIDA)

110t×6 6(AIDA)

200t×6、150t×1 7 (AIDA)

110t×6 6(AIDA)

Servo Presses

300t 1 (AIDA)

150t 1 (AIDA)

110t 1 (AIDA)

150t 1 (AIDA)

110t 1 (AIDA)

Transfer Press

30t 1 (OOSAWA)

Hydraulic Press

150t 1 (NAGASE)

Turret punch Press

1250×1250 1 (MURATA)

1270×2020 1 (TRUMPF)

1270×2020 1 (TRUMPF)

Welding machines

15~35kVA 14 (Panasonic)

Resistance Welding machine

50kVA 1 (Panasonic)

CO2 arc welding machines

300A 2 (Panasonic)

Tapping machines

10 (KIRA)

NC Shearing Machine

1 (KOMATSU)

Trichlorethylene washer

1

3D measuring machine

Projector

Horizontal type injection molding machines

450t 2 (TOSHIBA)

350t 2 (TOSHIBA)

230t 1 (TOSHIBA)

220t 3 (TOSHIBA)

180t 1 (SUMITOMO)

150t 1 (TOSHIBA)

100t 4 (TOSHIBA)

55t 1 (TOSHIBA)

350t 2 (TOSHIBA)

230t 1 (TOSHIBA)

220t 3 (TOSHIBA)

180t 1 (SUMITOMO)

150t 1 (TOSHIBA)

100t 4 (TOSHIBA)

55t 1 (TOSHIBA)

Vertical injection molding machine

55t 1 (YAMASHIRO)

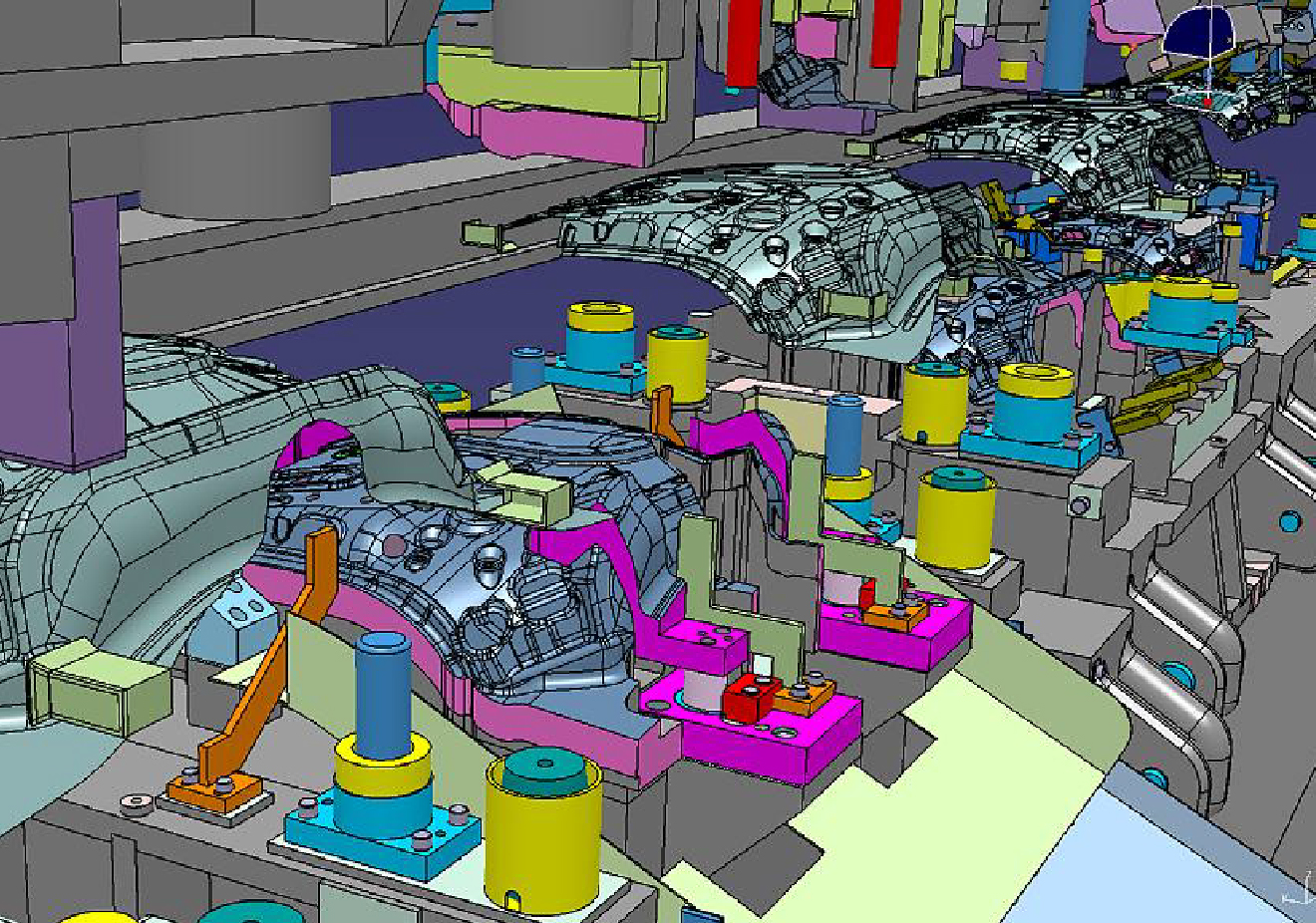

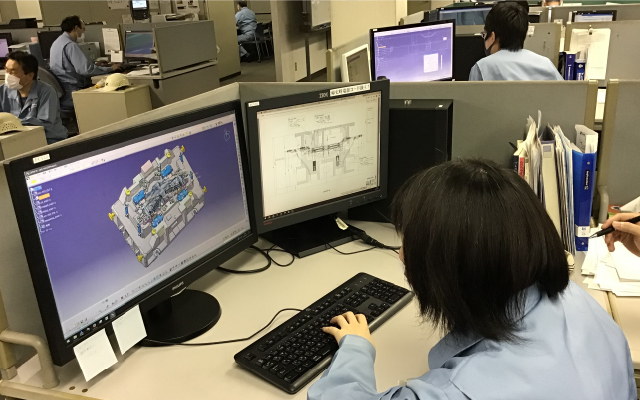

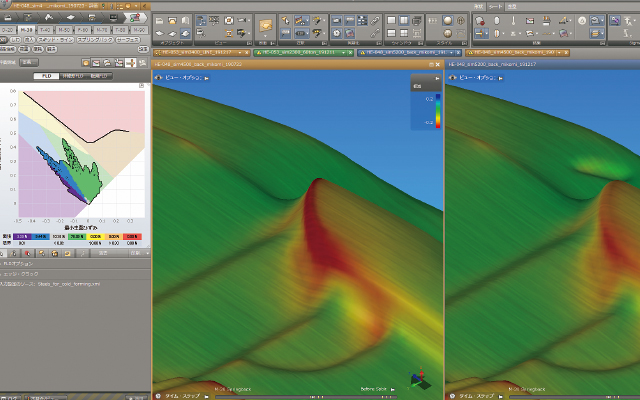

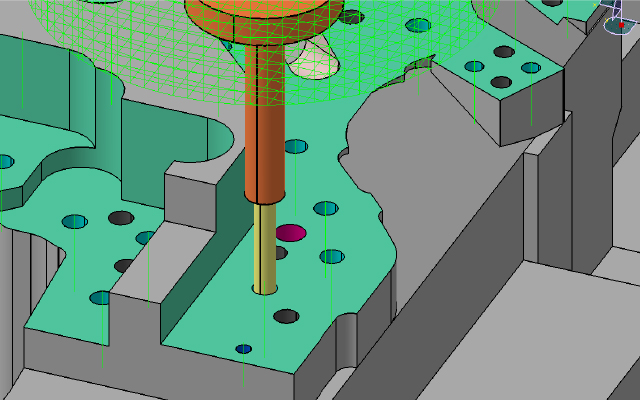

Equipment list of Production engineering / design / Inspection

We are the first company in Japan to introduce a 3D system for die manufacturing.

CAD

45 (CATIA Ver.5)

1 (ThinkDesign)

1 (EXCESS Hybrid)

1 (ThinkDesign)

1 (EXCESS Hybrid)

CAM

5 (WorkNC)

5 (iBlueCLIKS)

2 (CAM-TOOL)

1 (Tebis)

1 (CAMEST)

5 (iBlueCLIKS)

2 (CAM-TOOL)

1 (Tebis)

1 (CAMEST)

Sheet Metal Forming Simulation

1 (AutoForm)

1 (J-STAMP)

1 (J-STAMP)

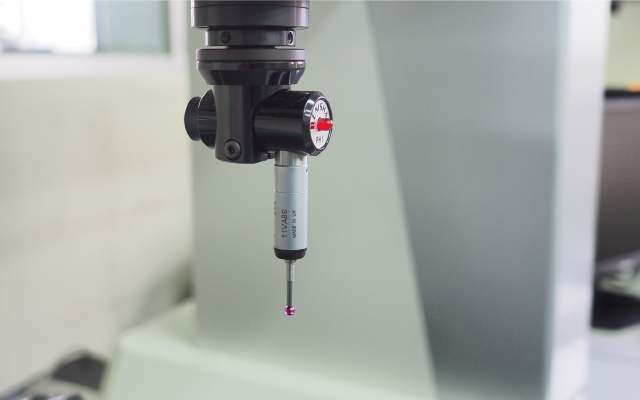

Inspection equipment for Die manufacturing

1 Contact type 3D measuring machine (DEA TORO)

1 Non-contact 3D measuring machine(MetraSCAN 3D)

1 Non-contact 3D measuring machine(MetraSCAN 3D)

Inspection equipment for Products

1 Contact type 3D measuring machine(AXCEL)

1 Profile Projector (PJ-A3000)

1 Profile Projector (PJ-A3000)

DNC Client/Server system

30 clients

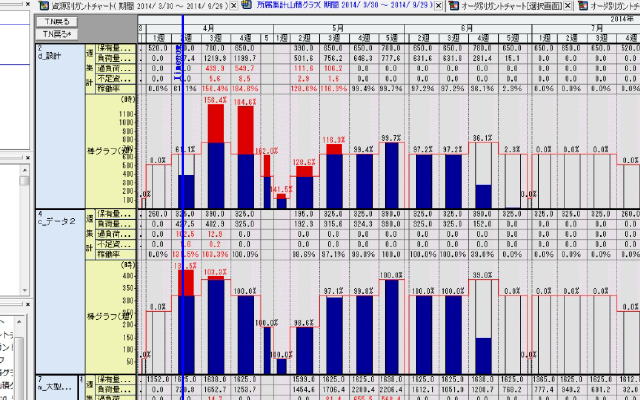

Achievement aggregation system

31 (ConMas i-Reporter)

Production management system

For Die manufacturing (in-house developed system)

For mass production (Ryu-jin)

For mass production (Ryu-jin)

Design support system

For Die design (in-house developed system TADD: TsubamexAutoDieDesignSystem)